Theory behind Alfa Romeo's points, coil and condensor

I have been told off for making my last article boring and far too technical! So in this article, I am going to take us back 40 years to a time when things were much simpler, we are going to cover contact breaker ignition. Contact breaker ignition consists essentially of four parts, an ignition switch, a coil, points and condenser. You will notice there were no acronyms in the olden days but some of the part names disguise what they really are, so an ignition switch is simply that, the coil is a transformer, the points are a simple switch and the condenser is a capacitor.

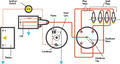

So how does it work? There is a transformer (the coil) which has two coils of wire connected by an iron bar. 12 volts are supplied to one coil of wire by the ignition switch but the electrical current can't flow as the other end of the wire is not connected to the negative terminal of the battery, the connection to the negative pole of the battery is made as the points close. As the points close current flows in the low voltage side of the wire in the coil, this flow of charge causes a magnetic field to be created in the iron bar. As the points open the magnetic field collapses, which induces a current in the other wire of the coil, this wire has a lot more coils of wire than the primary coil which increases the voltage to between 10,000 to 20,000 volts. This voltage travels to the nearest point that is connected to the negative terminal of the battery which happens to be the other side of the spark plug which means the spark has to jump the air gap of the spark plug igniting our petrol air mixture.

All that current flowing across the points does not stop suddenly when they are closed, and the current jumping the air gap as the points open causing a spark gradually erodes their tungsten contacts. The condenser cushions the spark by absorbing some of the current, making points life much longer but not infinitely long. As the contacts and the plastic rubbing block, which contacts the point cam, wear, the ignition points' clearance and timing constantly change. After thousands of miles, the timing has shifted enough to affect performance and the ritual of changing the points and setting the timing becomes necessary. How often? Some vehicles need to have the timing adjusted as often as every 10,000 miles to maintain peak performance. High-revving engines will need premium points with a high-pressure spring to keep the points from bouncing at increased revs. Some points assemblies include the condenser, yet for others, it's a separate part. Condensers are inexpensive enough that it makes no sense not to replace them with every set of points. They should last as long as a set of points, 20,000 miles at least.

Now the function of any ignition system is to create a spark in the combustion chamber at the correct point in the four-stroke cycle. This point is just before the piston reaches the top of its stroke, TDC, if it ignites the mixture too soon the resulting explosion will try to force the piston the wrong way down the bore which is known as pinking which can damage the engine. Contrary to how you would imagine an explosion to be i.e. it all burns at the same time, instead, the explosion starts at the spark plug and works to the outside of the combustion chamber. It takes some time for the fuel to burn, in the region of a thousandth of a second, in order that maximum pressure can be exerted on the piston for the longest possible time, as the speed of the engine gets faster then you need to move the point that the fuel is ignited to further before the piston reaches the top of its stroke. The spark will need to be fired somewhere between 8 degrees before TDC at idle, and 36 degrees before TDC at maximum revs. Incorrect ignition timing will cause problems with starting, lack of power decreased fuel economy and pre-ignition.

There are two main types of advance mechanisms built into the distributor. The first is the centrifugal advance. A pair of bob-weights spin atop the distributor shaft, restrained by small springs. As the engine speeds up, centrifugal force pulls the weights outward, which in turn makes the top of the split distributor shaft advance. Missing springs or a gummed-up linkage can give too much advance too soon, or none at all.

Similarly, a vacuum advance uses a rubber diaphragm to advance or retard the timing. Vacuum from the carburettor pulls on one side of the diaphragm, pulling the points around the distributor and making the plugs fire earlier. A leaky vacuum line, a disintegrating rubber diaphragm or a sticky breaker plate can make the advance mechanism balky.

Inoperative advance mechanisms can deliver too much or too little ignition advance. Too much advance can make the engine pink. Too little causes power loss and in extreme cases, overheating.

Installing the new points and condenser is simple, and usually requires no more than a screwdriver. The proportion of time the distributor's cam keeps the points closed and open is referred to as dwell angle. Adjust the dwell angle initially by using a feeler gauge, close is good enough, because the only really accurate way to set dwell is with a--wait for it--dwell meter. The dwell angle should be around 44 to 50 degrees for four-cylinder engines.

Before you refit the distributor cap, clean the points of any oil left behind by your feeler gauges. Contamination will carbonize and become a resistance where there should be only metal-to-metal contact. I usually just use the corner of a business card to scrub any contamination off. Add a dab of lubricant to the heel of the cam to ensure longevity.

Adjusting dwell also changes the base ignition timing, so whenever the dwell is adjusted or the points are replaced, the timing will need to be adjusted. Alfa engines need the vacuum advance disconnected in order to do the ignition timing. We always do the ignition timing with a strobe light so it is a very good idea to mark the timing marks with some Tippex to make sure you can see them. You will find three timing marks on most Alfas, TDC, initial advance and maximum advance. We always time cars up in our workshop at maximum advance which will occur at around 4000 rpm, we do this because most of the time your car will be running somewhere around these revs. It is also important to watch how the advance degrades as it comes back to idle, this is a common issue and can cause all types of problems when you come to tuning the carbs, what happens is the distributor does not return to the initial mark and stays to far advanced which in turn holds up the idle speed. This is caused by wear in the bob weights and springs which is difficult to rectify. It is a good idea to check the vacuum advance, this is easy all you need to do is connect a pipe to the vacuum advance unit and suck on the pipe while watching how the timing marks move, as you suck on the pipe the timing should advance.

To give you some idea of time, to set up and check a distributer will take between one and two hours but it is well worth the effort as your rewards with throttle response is much improved.